Home » Keywords: » optical measurement

Items Tagged with 'optical measurement'

ARTICLES

Optical measurement tools are picking jp steam, experts say.

Read More

At the Corner of Digital Twin and Perfect Part

Consider driving production with the shortest possible cycle time.

February 1, 2020

Shaft Measurement: What is the Best Tool for the Job?

Shaft measurement can be performed with a variety of metrology tools, from handheld devices to high-end coordinate measuring machines.

November 1, 2019

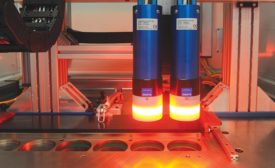

Blue Light Optical Scanning for High Resolution 3D Measurement

When an entire shape needs to be scanned, optical measurement is more effective.

September 1, 2017

Digital Advancements for Shop Floor Inspection of Medical Devices

A wide range of inspections and verifications are needed for these parts.

August 1, 2017

Optical Metrology Sees More

No other measuring method is capable of evaluating so many data points as quickly and as precisely as optical systems can.

May 1, 2017

Automatic Inspection of Industrial Gas Turbine Parts

How do you inspect such large, heavy and complex parts—with the required accuracy?

November 1, 2016

The Versatility of Vision Metrology

In the manufacturing world, speed and accuracy are high priorities. Vision technology provides both.

September 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing