Home » Keywords: » tensile testing

Items Tagged with 'tensile testing'

ARTICLES

Test & Inspection

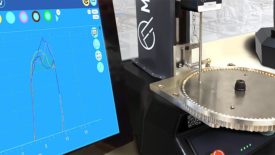

Materials Testing: Inside the Vascular Labyrinth

A trifecta of solutions for catheter testing and innovation.

August 22, 2024

Test & Inspection

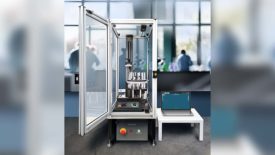

Universal applications and implementations of UTMs

A universal tester can regularly be found implementing tension and compression applications in QC and R&D environments.

April 18, 2024

Test & Inspection

Crushing it: a granular breakdown of testing what shouldn’t break down

While tensile testing garners significant attention, compression testing is equally crucial.

January 26, 2024

Test & Inspection

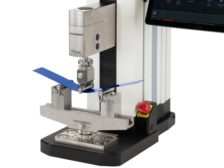

Important Considerations for Tensile Testing Equipment in Aerospace Applications

The most powerful tool a company has is the ability to follow a component failure back to the batch of material it was made from.

August 3, 2023

Tensile Testing: A Gripping Story

Tensile testing is varied in purpose and industry specific. The manner of holding the test specimen and applying the axis of tensile force is what makes the application unique and enables quality assurance at almost any point in any product's lifecycle.

July 28, 2023

Materials Testing

The Relationship Between Residual Stress State and Quality

Designing in, manufacturing for, and measuring residual stresses may be the most effective way to produce quality parts.

November 14, 2022

Tensile Testing: A Compressed “How-To” Overview

Let's start with the purpose, the practical and theory test.

November 1, 2022

Test & Inspection

Navigating Supply Chain Challenges with Force Testing

Recent advancements in force measurement equipment allow quality professionals to better handle unpredictable testing demands.

May 5, 2021

Essential Testing for Essential Industries

Force measurement is an important characteristic in meeting the requirements of a quality product.

August 26, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing