Home » Keywords: » verification

Items Tagged with 'verification'

ARTICLES

Measurement

Verification is checking the accuracy of the machine. Some people refer to it as calibration, but it is not.

Read More

Debunking the Myths of Fully Automated Inspection

Automated process control is more viable and less expensive than one might think.

June 5, 2018

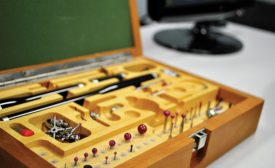

Calibration Considerations

Consider these factors before using the internal calibration feature on your device.

April 9, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing