Home » Keywords: » vision sensor

Items Tagged with 'vision sensor'

ARTICLES

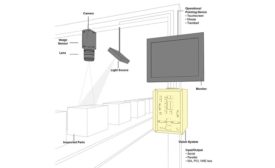

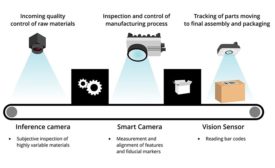

Before you can fully utilize machine vision, you need to understand the basics.

Read More

Smart Camera Evolution

The evolving capabilities of cameras with onboard intelligence are creating new opportunities for the industry.

May 1, 2019

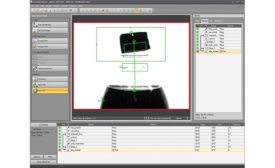

Vision Sensors Set New Standard for Pass/Fail Inspections

By combining powerful vision tools, simple setup and a modular design, vision sensors set new standards for value, ease of use and flexibility.

April 30, 2018

The Capabilities of Vision Sensors

Let’s take a look at the capabilities and potential applications of vision sensors.

January 8, 2018

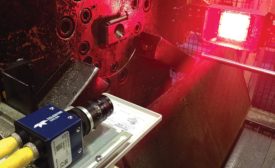

Smart Cameras in a Manufacturing Environment: Today and in the Future

The combination of dramatically improving hardware and modern software technology has made smart cameras capable, inexpensive, and easy-to-use.

January 1, 2018

Machine Vision Trends

MOST NOTICEABLY THERE IS A MOVE INTO THE THIRD DIMENSION.

December 16, 2015

Recent Advancements in Vision Technology for Product Inspection

TODAY IT’S POSSIBLE TO OBTAIN THE BENEFITS OF MACHINE VISION ON A WIDER RANGE OF APPLICATIONS WHILE AT THE SAME TIME INCREASING INSPECTION ACCURACY AND REDUCING APPLICATION DEVELOPMENT TIME.

July 8, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing