Home » Keywords: » interface

Items Tagged with 'interface'

ARTICLES

Vision & Sensors | Interfaces

This new wave of interface design choices is significantly influenced by the electronics, mobile, and personal computing markets.

Read More

Three Cornerstones of Smart 3D Machine Vision

Modern UI design, web-enabled 3D smart sensors, and onboard inspection software.

November 28, 2020

Multi-Sensor Metrology Advances

Advancements in multi-sensor platforms combine the best features of vision and touch-probe inspection for maximum accuracy and speed.

August 4, 2020

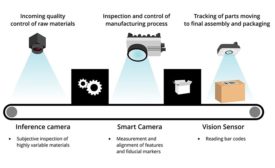

Interfaces for Machine Vision

Both consumer and dedicated interfaces are used across many machine vision applications.

May 5, 2020

Applying the CoaXPress Interface in Multi-Camera Machine Vision Systems

Multiple camera systems have been a fixture in machine vision for decades. What is new is the use of CXP.

January 1, 2020

Smart Camera Evolution

The evolving capabilities of cameras with onboard intelligence are creating new opportunities for the industry.

May 1, 2019

Cross-Industry Collaboration Can Fuel Machine Vision Innovation

Machine vision applications have grown exponentially.

January 8, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing