Home » Keywords: » battery

Items Tagged with 'battery'

ARTICLES

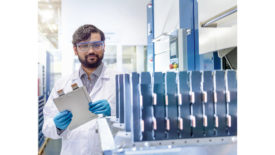

NDT | Leak Testing

Leak Detection’s Crucial Role in Li-ion Traction Battery Production

Manufacturers that routinely challenge their leak tightness testing process will consistently produce products with reliable performance, battery longevity and safety.

January 9, 2024

NDT | Computed Tomography

The most effective and precise battery inspection technology

It’s the tiniest defects that are the major problems today.

January 8, 2024

NDT | Computed Tomography

Creating the Future of Mobility with CT Inspection of Batteries

Industrial x-ray and CT inspection supports quality control and failure analysis at all stages of a battery's lifecycle.

September 21, 2023

Test & Inspection

Hardness Testing of Individual Battery Electrode Particulates

Recently, researchers have shown correlation between particle hardness and cycle performance.

April 4, 2023

Standardized Leak Testing for Lithium-Ion Battery Cells

It is Essential for Automakers.

January 6, 2021

NDT Leak Testing

Leak Testing Meets New Energy Storage Needs

Leak tightness is a major criterion for stable performance of a battery pack over the expected lifetime of an electrical vehicle.

August 5, 2020

E-Mobility Inspection

With electric vehicles on the rise, so too are the inspection applications.

August 1, 2020

Introducing E-Mobility Inspection

Meet the quality inspection solutions for all components of E-Mobility: Battery, Power Electronics, E-Motor and Transmission.

January 2, 2020

5 Important Reasons to Check for Leaks in Battery Manufacturing

For quality, durability and safety, leak testing is critical.

July 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing