Home » Keywords: » safety standards

Items Tagged with 'safety standards'

ARTICLES

Management

Preparing for these missions involves a series of quality related tools and practices, many of which might also be found in manufacturing.

Read More

Software

The Key to Maintaining Safety and Compliance in Manufacturing

Safety and compliance in manufacturing touches nearly every aspect of the business.

March 19, 2024

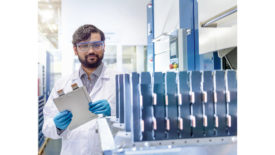

NDT | Leak Testing

Leak Detection’s Crucial Role in Li-ion Traction Battery Production

Manufacturers that routinely challenge their leak tightness testing process will consistently produce products with reliable performance, battery longevity and safety.

January 9, 2024

A Pandemic is No Match for Industry 4.0

While COVID-19-related disruptions threatening to upend manufacturing as we know it, IIoT systems make large-scale remote work possible, improve safety and help with supply chain issues.

September 28, 2020

Back to Basics: Impact Testing

Beginner tips to understand impact test methods and standards.

September 4, 2018

INDUSTRY HEADLINE

SGS-TÜV Saar Offers Vehicle Manufacturers Training for New Safety Standards

February 19, 2018

Are Your LED Lights Safe?

WHITE LEDS ARE WIDELY USED IN INDUSTRIAL AND ARCHITECTURAL LIGHTING APPLICATIONS.

January 7, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing