Home » Keywords: » universal testing machine (UTM)

Items Tagged with 'universal testing machine (UTM)'

ARTICLES

Test & Inspection

Documenting material properties is often a key factor in quality control and R&D divisions.

Read More

Test & Inspection

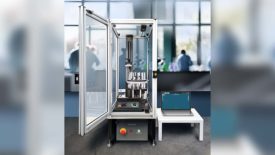

Universal applications and implementations of UTMs

A universal tester can regularly be found implementing tension and compression applications in QC and R&D environments.

April 18, 2024

NDT | Compression Testing

Understanding Compression Testing and Flexural Modulus, a Crucial Aspect of Material Strength Evaluation

Advancements in materials science and engineering breakthroughs are possible through the science of compression testing.

October 6, 2023

Tensile Testing: A Gripping Story

Tensile testing is varied in purpose and industry specific. The manner of holding the test specimen and applying the axis of tensile force is what makes the application unique and enables quality assurance at almost any point in any product's lifecycle.

July 28, 2023

Peel Applications

Lengthwise force testing for adhesives and interlocking materials.

February 8, 2021

A guide to Force Measurement in Static Materials Testing

Force testing is the most fundamental element of materials testing and continues to be critical to the safety of the world around us.

October 6, 2020

Retrofits: Ensuring the Reliability and Capability of Your Universal Testing System

When considering legacy equipment in your lab it is important to recognize what makes a good candidate for a retrofit.

October 1, 2019

The Universality of a Universal Testing Machine

A staple of quality control laboratories around the world, a UTM is an indispensable asset to quality and engineering professionals.

April 1, 2017

Tensile Testing Machine Basics

Learn more about testing solutions available today.

October 1, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing