Home » Keywords: » safety in manufacturing

Items Tagged with 'safety in manufacturing'

ARTICLES

Management

The heart of Boeing’s manufacturing operations lies in its ability to deliver flawless aircraft to customers.

Read More

Face of Quality | Jim L. Smith

Organizations Need to Include Quality as a Core Business Strategy

Quality is Core

June 3, 2024

Software

The Key to Maintaining Safety and Compliance in Manufacturing

Safety and compliance in manufacturing touches nearly every aspect of the business.

March 19, 2024

NDT | Leak Testing

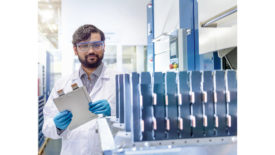

Leak Detection’s Crucial Role in Li-ion Traction Battery Production

Manufacturers that routinely challenge their leak tightness testing process will consistently produce products with reliable performance, battery longevity and safety.

January 9, 2024

NDT | PMI Part 3

Evolution of PMI Technology: Advancements in Handheld XRF Propel Accuracy, Connectivity, and Efficiency

The suite of tools available for PMI has grown.

October 13, 2023

NDT | PMI Part 2

On-Site and Real-Time PMI Testing: Faster Decisions, Enhanced Productivity, and Cost Savings

Learn more about the advantages of positive material identification (PMI) testing.

October 12, 2023

NDT | PMI Part 1

Ensuring Quality and Safety in Manufacturing: The Role of Positive Material Identification

PMI is a vital nondestructive testing method for quality assurance and safety.

October 11, 2023

Inaugural Quality Rookie of the Year Winner

2023 Quality Rookie of the Year: Jared Curtis, Time for a Challenge

Our Rookie of the Year had twenty years of experience when he decided to switch careers.

May 1, 2023

Looking to the Future: How to Keep Microscope Users Safe from Cross-Contamination

There are significant health benefits associated with eyepiece-less microscopes compared to eyepiece microscopes.

September 1, 2020

Compliance Today

No matter what is going on in the world, you can feel prepared.

June 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing