Home » Keywords: » American Society for Testing and Materials (ASTM)

Items Tagged with 'American Society for Testing and Materials (ASTM)'

ARTICLES

Quality 101

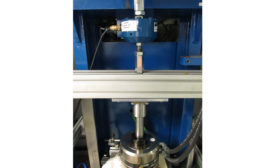

Materials testing submits a material or product to a thorough, in-depth "check-up" to ensure overall quality.

Read More

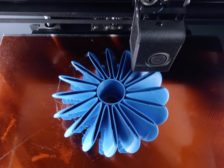

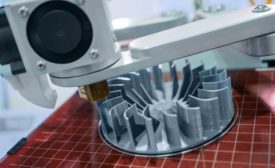

Additive Manufacturing Standards

Manufacturers should be aware of the many standards for this technology.

May 7, 2021

NDT Compliance: The Proper Test for High Quality Lamps

Standards are constantly getting upgraded to make NDT safe and reliable for inspectors and the public.

November 8, 2019

NDT

Materials Testing Standardization in Metal Additive Manufacturing

Even with the use of existing standards, several notable gaps remain.

October 1, 2019

Additive Manufacturing Standards Aim to Keep Pace with Technology

ASTM launches Additive Manufacturing Center of Excellence with industry partners.

August 1, 2018

Turn and Face the Strain

A Q&A with Instron’s Peter Bailey and Exova’s Jonathon Pugh on the evolution of fatigue testing in the aerospace sector.

July 1, 2016

A Deep Dive into NDT Standards

Two nondestructive testing experts explain the standards process.

June 9, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing