Home » Keywords: » laser scanning

Items Tagged with 'laser scanning'

ARTICLES

In recent years, laser scanning hardware and software have improved considerably, resulting in a streamlined system that can capture vast detail rapidly.

Read More

Manufacturers Show Their ‘Metal’ Using the Imaging Power of Digital Microscopes

Improving the quality of metal-based products.

December 6, 2019

Depth Gaging from Top to Bottom

A wide variety of depth gages are available for any application.

July 8, 2018

INDUSTRY HEADLINE

Former Boeing CTO John J. Tracy Brings Aerospace Expertise to 3D Systems Board of Directors

July 11, 2017

Reverse Engineering: A Basic How-To

The advancements in technology over the last 20 years have been amazing.

June 1, 2017

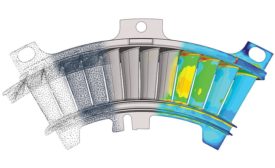

Reverse Engineering Continues to Expand its Role in Industry

Reverse engineering parts and systems enable aircraft to keep flying or machines to keep running.

October 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing