Home » Keywords: » structured light

Items Tagged with 'structured light'

ARTICLES

The measurement of surface finish has come a long way in the past 70 years.

Read More

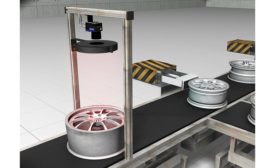

Choosing the Right 3D Scanner

A quality engineer describes how he picks the right tool for the job.

October 1, 2018

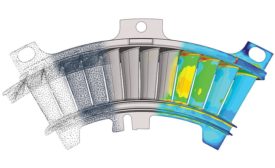

Reverse Engineering: A Basic How-To

The advancements in technology over the last 20 years have been amazing.

June 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing