Home » Keywords: » geometry

Items Tagged with 'geometry'

ARTICLES

Contact stylus and noncontact optical can show excellent correlation.

Read More

Does Air Gaging fit into a Modern World?

Air gaging is an extremely fast measurement method even when measuring difficult geometries.

September 2, 2020

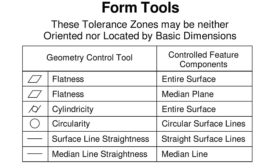

Empowering GD&T

Based on the ASME Y14.5 2009 Standard. Without GD&T, manufacturing is a guessing game.

June 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing