Home » Keywords: » thickness gauges

Items Tagged with 'thickness gauges'

ARTICLES

NDT Back 2 Basics

It enables new tools that can transform the inspection process.

Read More

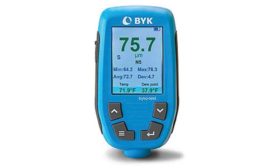

The Current State of Thickness Measurement

Optical measurement tools are picking jp steam, experts say.

June 29, 2020

Exploring the benefits of noncontact thickness metrology

Noncontact thickness metrology solutions have become a necessity for the manufacturing sector.

October 15, 2019

Where to Start with Ultrasonic Thickness Gaging

There are a wealth of resources for understanding the basics and newest advances in ultrasound.

August 15, 2018

Calibration Considerations

Consider these factors before using the internal calibration feature on your device.

April 9, 2018

NDT HEADLINE

Carestream NDT Signs Baugh & Weedon as New Representative Covering UK and Ireland

August 15, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing