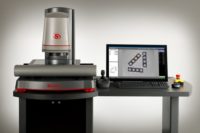

Vision Sensor

The Checker 3G Series allows operators to choose whether to configure the sensor as a presence or measurement sensor. Presence sensors verify that features are present, while measurement sensors verify that features are the correct height, width and diameter. In either mode, there is no limit to the number of part features that a single sensor can inspect. The sensor is able to detect and track more than 6,000 parts per minute in varying positions along the production line, overcoming imprecise part positioning and delivering consistent, precisely timed pass/fail results.

The device does not require a PC for setup. Instead, the teach pendant allows operators to set up jobs on the production line and have them running in minutes. A single teach pendant can be used to set up any number of sensors and can remain connected for real-time application monitoring.

Cognex Corp.

(508) 650-3000

www.cognex.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!