Poor GR&R Percentage, Now What?

Examining the components of a GR&R study can lead to the source of greatest variation in the measurement system.

You have just finished your R&R study. Everything has gone according to plan and you are feeling quite pleased. Yet there is something off, something wrong. Your R&R percentage is too high. Now what?

TECH TIPSThe goal of a GR&R study is to determine whether the right measurement system is in place. The R&R percentage is an overall grade that can be expressed to management, auditors, and customers. When the percentage is low, it describes a measurement system that is capable of your critical measurements and no action is needed. However, when the R&R percentage is higher than the allowable requirements, plans and action are demanded of the quality managers in charge of the measurement system. |

First, let’s get some of the basic assumptions out of the way.

- You selected the parts to be used for the study randomly, and there is little chance the similarity of the parts is affecting the outcome.

- Next, you organized the appropriate appraisers for the experiment. They are the typical users of the gage.

- Finally, you have reviewed the measurements taken and double checked the results were calculated correctly. If you aren’t sure these steps were taken, this might account for the poor results. In that case, redo the study and correct any flaw in the design of the experiment.

Once you have ensured that the study was conducted correctly, the task of digging in and interpreting the results begins. Remember what the goal of a GR&R study truly is: to determine whether the right measurement system is in place. The R&R percentage is an overall grade that can be expressed to management, auditors and customers. When the percentage is low, it describes a measurement system that is capable of your critical measurements and no action is needed. However, when the R&R percentage is higher than the allowable requirements, plans and action are demanded of the quality managers in charge of the measurement system.

For this article, we are using the MSA’s R&R calculations and standards. A general guideline for the R&R percentage is as follows:

There can be a gray area for an R&R percentage between 10-30%, and often the deciding factor remains with the customers who requested the study. They have the final say as to what is acceptable based on their needs.

Let’s say we are working for customer Must B. Wright Inc. and they have demanded that R&R results must be below 20%. Take the sample data from page 105 of the MSA 4th Edition manual as our example study data.

When the numbers are crunched and the results are gathered, we find that the R&R is 26.68% for the study parameters, a percentage that is higher than that which the customer determined to be acceptable. So where do we begin to make the required improvements?

Some managers make the mistake of wanting to change everything about their measurement system to chase a better R&R percentage. This is a shotgun approach and more damage can actually be done with this approach. Instead, a precision rifle can hit the target without needlessly destroying everything in its path. That is the mentality that we need, so first we must examine what contributes to the overall R&R percentage.

The equipment variation (EV) is related to the repeatability, and the appraiser variation (AV) is for the reproducibility. When combined using the MSA formulas, these lead to a base GR&R number. Dividing the GR&R by the total variation in the study and then multiplying by 100 yields our R&R percentage. So naturally, examining the EV and the AV is a good start to determining the next course of action for improvements.

Sources of variation can come from many places for EV and AV and these can often be broken down into five common factors:

- Materials – parts/units to be measured

- Machine – gage or tool used to take the measurement

- Manpower – appraisers taking the measurements

- Method – procedure followed

- Milieu or Environment – surroundings of the study such as temperature and humidity

In the example study data, the EV comes out to 17.62%, while the AV is 20.04%. To avoid tweaking everything, we can focus our sights on the higher value, which is the appraiser variation. The manpower and method are factors that can affect the AV, so we can direct our attention there for improvements to be made.

The manpower relates to the appraisers who were used for the R&R study. They should be the regular users of the gage that take the everyday measurements. If the administrator of the study has taken notes during the experiment, these can be reviewed for anything relating to the people as they took the measurements. “Appraiser A was noticeably tired from working a full shift before participating in the study and Appraiser C didn’t wear his prescription glasses.” Also, reviewing the training that these appraisers have undergone can help determine if more training is necessary before the next scheduled R&R study.

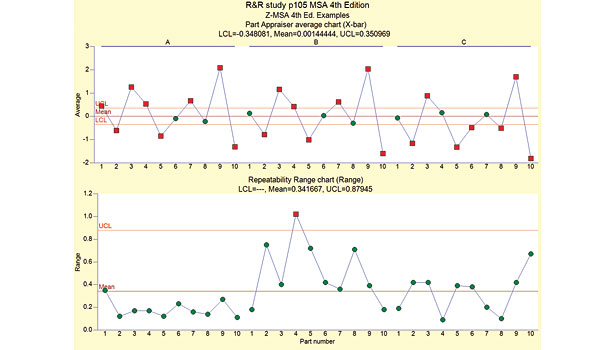

Many of the software packages that can calculate R&R results will provide charts that can be used to diagnosis sources of variation. In our example, an Xbar and Range change can show basic measurement agreement as well as which appraiser has the most variation in their measurements between replications.

While the appraisers have reasonable agreement in their measurements we can see Appraiser B has the most variation between her measurements. Before you fire B, it can be good to review other charts as well, such as an appraiser inconsistency and appraiser bias chart, to gather further information for courses of action.

The second factor to review is the method that the appraisers used to take the measurements. The procedure for how the measurements are to be taken with the gage can be a critical piece of a measurement system. If the procedure is outdated or it was noted during the experiment that not all the appraisers were following the approved method, this could account for much of the high AV percentage. Reviewing the procedure with the appraisers and updating where necessary could help reduce measurement variation.

After speaking with the appraisers and reviewing the experiment notes, we have identified in our hypothetic study that two of the appraisers were trained inadequately by a retired employee and no one was using the approved procedure for taking the measurements. The quality manager can then institute a documented training plan for the gage operators and review and revise any or all measurement procedures. Once progress of the new plan has been sufficiently put in place, a second R&R study can be conducted using the same conditions as the first and using the same parts if available. The results can be reviewed to determine if the changes enacted correspond to a lowered R&R percentage and a better measurement system.

No one wants to stare at a poor R&R percentage when a customer such as Must B. Wright Inc. is looming over your shoulder. Yet, many of us find ourselves in this position each day. Examining the components of a GR&R study can lead to the source of greatest variation in the measurement system. Once that has been identified, managers can work to reduce the variation and leave the customers happy and satisfied for the future.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!