Capturing the Third Dimension for Machine Vision

New technologies now in development may help make 3D more accessible for a larger number of manufacturers.

An advanced structured light system now in development combines digital fringe projection and patented software techniques to match the cost benefits of digital systems while rivaling the performance of analog approaches.

Designers can choose from a range of different technologies for 3D imaging, with some delivering better performance for manufacturing and quality inspection processes.

3D imaging brings more detailed analysis and insight to manufacturing and quality inspection processes where depth information can help verify proper assembly and detect surface defects. Where 2D inspection provides X and Y values for an object, depth information can be used to verify the proper position and height of components on a circuit board or automate pass/fail decisions to screen out flawed products.

While 3D has quickly become commonplace in our consumer lives—with 3D films, televisions, gaming consoles, printers, and more—some approaches to capture the third dimension are too costly, complex, or don’t deliver the required accuracy for automated quality inspection of high-precision parts. With 3D image technologies on the market today, integrators and designers are forced to make tradeoffs between performance accuracy, image acquisition time, and in some cases end-user safety to meet budget demands.

Despite these challenges, 3D imaging is finding a place in manufacturing inspection. Various technologies are available that rely on different approaches to capture depth detail, with advantages and disadvantages often dependent on application requirements. New technologies now in development are also emerging that address the performance and price gap, and may help make 3D more accessible for a larger number of manufacturers.

Laser Triangulation

Laser triangulation uses a traditional 2D camera and a laser light source to provide extremely accurate depth measurements. In these systems, a camera records laser lines or dots that scan the object to be measured. The object can be moving across a conveyor belt, or the camera can be moved across the object. By knowing the position of the camera and laser and their angle with respect to the object, the processor calculates the changing position of the laser to determine depth.

This system delivers extremely high accuracy, and can be a good solution in difficult lighting conditions. However, the system requires either the object or the imaging system to move steadily and precisely during the scanning. This adds to component costs, and a more complex setup is required to ensure high accuracy. The slow image acquisition time makes the system unsuitable for some high-speed manufacturing inspection applications. In addition, there are eye-safety concerns for end-users of the laser-based system.

Time-of-Flight

Time-of-flight systems are an efficient method to calculate depth data and distances that measure the time required for light to travel from the imaging device to the object. Time-of-flight relies on two different methods to scan objects. Continuous wave systems measure phase length for a light source, and support only low resolution scanning. The other approach, which measures distance based on precise light pulses, is better suited for higher resolution requirements.

In both systems, the light source hits the inspected object and is reflected back to a camera sensor. The time required for the light to travel to the object and return to the sensor provides the depth value. These systems are inexpensive and require a limited number of components: a light source, integrated lens, and time-of-flight sensor.

A time-of-flight system’s ability to measure distances with a complete scene, versus scanning required for laser triangulation, combined with high-frame rate cameras makes this approach suitable for real-time applications. The technology has been used in crash avoidance and pedestrian awareness systems for automotive driver assistance applications, gaming consoles that use cameras for gesture recognition, and robotic sorting systems. While the systems are comparatively inexpensive, they are not as effective when operating in variable light conditions or when scanning mirrored or reflective objects, and accuracy can be plus or minus a millimeter.

Stereo vision and Structured Light

A third approach to 3D imaging is stereo vision, which uses two cameras to record an object from different positions. Processing software then reads the images, and based on the known position of each camera and the geometry of the scanned object compares the differences to construct a 3D image.

These systems can be built using low-cost area scan cameras, however the processing required to search for corresponding points in the two images consumes excessive computing power and makes the technology unsuitable for real-time requirements. The technology can’t scan consistent surfaces, as defined reference points are required to compare the two images.

To improve stereo vision, one option is to add structured light to the solution. With fringe projection systems, a projector displays geometric patterns on the object to be imaged. As a result, the measurements can be more precise and limitations concerning homogeneous surfaces and low or changing lighting conditions are removed. Structured light systems can accurately inspect a variety of surfaces, including matte, gloss, and highly reflective metallic or mirror-light objects. With proper calibration, these systems can be designed using a projector and a single camera to reduce component costs.

A New Approach to Structured Light

With fringe projector technology, integrators have two technology options. Traditionally, fringe projection systems have been designed with analog projectors. The analog projector displays perfectly smooth sine waves on the object being inspected to produce a highly accurate 3D model. However, these systems are prohibitively expensive for most vision inspection applications due to the high cost of the analog projector. In addition, moving mechanical parts within the projector pose a potential point-of-failure.

To counter these concerns, one option is to replace the analog projector with a digital projector. In comparison, digital projectors are very inexpensive, and moving parts (the color wheel) can be removed as only monochrome imaging is required. However, most digital fringe projection systems on the market today supported limited resolutions and the projected sine waves projected are not perfectly smooth, resulting in poor overall performance.

A more advanced structured light system is now in development that combines digital fringe projection and patented software techniques to match the cost benefits of digital systems while rivaling the performance of analog approaches.

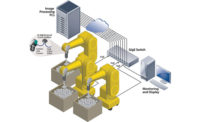

This fringe projection system uses a low-cost digital micromirror device (DMD) projector, high-speed machine vision camera, and patented software techniques that simulate analog sine waves. This results in systems that are far less expensive than an analog approach, while delivering much higher accuracy than digital systems.

A conventional structured light system can generate about 4 million 3D pixels per second with an “easy” matte object. In comparison, the advanced digital fringe projection system generates approximately 12 million 3D pixels per second under the same conditions, allowing for faster inspection and increased throughput. The system can find defects that are as small as 30 micrometers (µm) wide and 15 µm deep—nearly impossible to see with the human eye. Compared with analog systems, the fast acquisition time—milliseconds per object—enables precise inline inspection of parts as they move on a conveyor belt.

There is increasingly demand for 3D inspection in machine vision, but to-date the cost, complexity, or limitations of systems on the market today either make its use economically unfeasible or impractical. With new fringe projection systems that combine the performance of analog with the cost-benefits of digital, 3D inspection is now within reach for a wider range of manufacturing inspection applications.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!