John Phillips

John Phillips is senior product manager at Pleora Technologies Inc. (Kanata, Ontario, Canada). For more information, call (613) 270-0625, e-mail john.phillips@pleora.com, or visit www.pleora.com.

ARTICLES

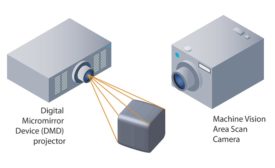

New technologies now in development may help make 3D more accessible for a larger number of manufacturers.

Read More

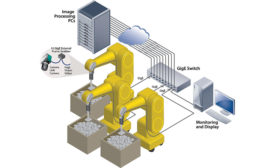

Fueling Innovation in Machine Vision

Advances from the networking industry are again set to help support next-generation imaging systems.

December 1, 2016

The Human Side of Machine Vision

VISION STANDARDS ARE ADVANCING THE DESIGN OF NEW MACHINE VISION TECHNOLOGIES WHILE STILL ADDRESSING THE HUMAN NEED FOR SIMPLE TO USE SYSTEMS.

December 16, 2015

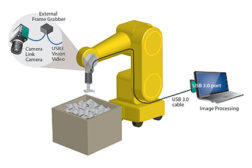

Vision Technologies and the Rise of the Robot

MANUFACTURERS ARE NOW ACTIVELY SEEKING NEW SOLUTIONS THAT CAN HELP FURTHER BOOST PERFORMANCE AND LOWER COSTS.

May 5, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing