Thread Classes and Setting Plug Gages

Product tolerances and dimensions always dictate the gage tolerances and dimensions.

Thread classes for product threads, and by extension the gages used to inspect them, can become a bit of alphabet soup. Some find the requirements confusing. The confusion generates questions and assumptions. If “2A” is for an external thread, why does it apply to the thread setting plug? Why am I unable to order a class “6H” “M” series metric thread ring gage? What is wrong with using a class “6g” setting plug gage to measure internal product threads?

To answer these questions, we must first have a basic understanding of the product threads we are making. This also requires knowledge of industry standards that govern the product threads and the selection of measuring tools. This selection is based on the product thread requirements. The product dimensions dictate the gage dimensions and tolerances. (i.e.: unified inch screw threads per ASME B1.1-2003 are inspected with gages manufactured per ASME B1.2-1983.) Once we understand what we need to measure, we can develop or purchase tools to insure the mating product threads will assemble. The geometry of the thread form or design can make this challenging.

This is one of the reasons that the ANSI, ASME, FED, Mil, ISO, DIN… standards are created. These standards are guides that, if followed, insure the proper assembly of the mating product threads. To this end, they have developed an identification system that when properly applied, insures the product will assemble and function as designed, if the mating products pass the defined inspection tools. One critical part of the identification system is the “thread class.”

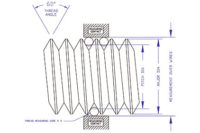

Figure 1. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and M Series metric screw threads and how the classes relate to each other.

Per ASME B1.1-2003, “thread classes are distinguished from each other by the amounts of tolerance and allowance.” The “allowance” is the adjustment made to one or both threaded mating parts of the assembly to insure they will assemble with the designed fit (how lose or tight the thread assembly is). Another term we will need to understand is “basic pitch diameter.” The basic pitch diameter is the nominal (mean) pitch diameter of the product assembly, internal and external thread. It is the base value for the application of the thread class and allowance. Figure 1 illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and M Series metric screw threads and how the classes relate to each other.

The allowance for unified inch screw threads per ASME B1.1-2003 is only applied to the external product thread. Unified inch screw threads have the following thread classes. Internal UN Series threads are all specified using a capital letter “B” (i.e.: 1B, 2B or 3B). External UN threads are defined by a capital “A” (i.e.: 1A, 2A or 3A). External UN threads are where the allowances are applied. The external class 1A and 2A thread classes have an allowance applied that makes the pitch diameter smaller than the basic pitch diameter. The result is a thread that does not have an interference or line fit. The class 3A threads do not have an allowance. A UN thread description example is shown in Figure 2.

Above: Figure 2. A UN thread description example is shown here.

Right: Figure 3. Metric threads have an additional feature that allows them to state a tolerance grade and position for both the pitch diameter and the major diameter for external product threads and minor diameter for internal product threads.

Metric M Series screw threads per ASME B1.13M-2005 have their thread classes defined by a numeric “tolerance grade” and an alpha “tolerance position.” Metric threads have an additional feature that allows them to state a tolerance grade and position for both the pitch diameter and the major diameter for external product threads and minor diameter for internal product threads. (See Figure 3.)

External metric product threads will have a lower case tolerance position (i.e.: 6g, 4g, 4g6g…). Internal metric product threads will have an upper case tolerance position (i.e.: 6H, 4H, 4H6H…).

All of this description and thread class information flows from the product directly to the gages. If the product drawing for an external thread states ¼-20 UNC 2A, this same description and thread class is used to order the thread ring gages to inspect the external product thread. The same is true for an M6 x 1.0 6g external thread. You would order an M6 x 1.0 6g go / no-go ring gage set to inspect it. Internal threads work the same. A class 2B working plug gage is used to inspect a class 2B internal product thread. A Class 6H metric internal thread is inspected with a class 6H go / no-go working plug gage.

Truncated setting plug gages for adjustable thread ring gages tend to cause some problems and confusion. Many of these problems are due to misunderstanding the purpose of the truncated setting plug gage. Truncated setting plug gages have only one purpose. They are used to calibrate and set adjustable thread ring gages. A truncated setting plug should never be used to inspect an internal product thread. Thread setting plugs have the same pitch diameters as the adjustable thread rings they set/inspect. The setting plug gages will have a go pitch diameter that is larger than the no-go pitch diameter. If someone used a truncated setting plug to inspect internal product threads, they would produce 100% scrap. Any internal product thread the go setting plug entered, would also allow the smaller no-go to enter.

Example:

¼-20 UNC 2A Go / No-Go Thread Ring Gage,

Go PD = .2164 / No-Go PD = .2127

¼-20 UNC 2A Go / No-Go Truncated Setting Plug Assembly, GO PD = .2164 / No-Go PD = .2127

¼-20 UNC 2B Go / No-Go Working Plug Assembly,

GO PD = .2175 / No-Go PD = .2224

The thread class on a truncated setting plug matches the thread class of the adjustable thread ring gage it is used to set, inspect and calibrate. A class 2A set plug is used to only inspect a class 2A adjustable thread ring gage. A class 6g truncated setting plug is used to inspect only a class 6g adjustable thread ring gage.

In some situations, we make what we believe to be logical assumptions. A machine shop is asked to make a mating internal thread for the external thread they are presently manufacturing. The external thread is a 3/8-24 UNF class 2A. They assume that the internal thread must have the same 2A class of fit as the external thread they presently manufacture.

Based on this assumption, they contact their gage distributor / manufacturer and order a 3/8-24 UNF 2A plug gage. The only 2A plug gage that exists is a setting plug. They receive the 2A setting plug and begin manufacturing and inspecting product. Manufacturing grinds to a halt. Every part they are making that passes the 2A go plug, passes the 2A no-go plug, 100% scrap. The gage must be wrong. Send the gage for calibration or return it and get another one ASAP. The new gage comes in and the problem persists. Things spin out of control. Assumptions become questions. Questions become accusations.

Figure 4. This shows some typical product thread assembly class correlations.

The problem is not the gage or the cutting tool. The problem is the assumption. These assumptions can come from a drawing with a typo or a description error. They can also follow the previous scenario. These mistakes happen to both experienced and new engineers, machinists and buyers. In the above example the gage for the internal thread should have been a 3/8-24 UNF 1B, 2B or 3B. The “B” is the indicator per ASME for the internal product thread and the gages used to inspect it. Had the example been for an M6 x 1.0 6g product thread the scenario would be the same. The internal thread should be an upper case letter “G” or “H.” If a class 6g setting plug were used to inspect product threads, the results would fail the same as they did with the class 2A in the example.

Figure 4 shows some typical product thread assembly class correlations. These are for a general reference. As shown in Figure 1, a 1A, 2A or 3A external product thread will assemble with a 1B, 2B or 3B internal product thread. The control for how loose, tight or strong the product thread assembly is driven by the selection of the thread class based on the product requirements.

Product tolerances and dimensions always dictate the gage / measuring tool tolerances and dimensions. Using the correct thread designation and thread class per the applicable industry standard insures the products manufactured will assemble and function as designed. Do not assume. Please ask questions if you are not sure. It may take a little extra time to ask a question and get an answer. That time pales in comparison to the cost and impact to delivery that specifying, ordering or using the incorrect gage will cost. Q

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!