Form Measurement in the Electric Vehicle Industry

Form measurement is the ability to identify the shape, size and location of specific 2D or 3D features.

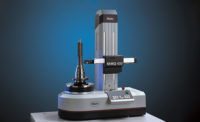

A surface machine utilizing a special, small stylus evaluates surfaces and tiny, hard-to-reach features of a component for roughness and waviness.

While electric vehicles (EV) aren’t new, they are gaining traction and popularity across the globe.

This surge in demand has led to an increase in the development and manufacture of new devices and parts that differ from those in gasoline and diesel vehicles, yet which still require accurate measurement. This is where form measurement comes into the picture.

How form measurement works

Form measurement is the ability to identify the shape, size and location of specific 2D or 3D features. In terms of the EV industry, here we will focus on 2D form measurements in two categories: contour and surface roughness.

Contour measuring equipment is more commonly used to measure features ranging from a few millimeters down to microns, while surface finish equipment will measure surface callouts from a few microns, down to sub-nanometers. These measurements are performed by tracing across a part using a stylus with a small radius, and plotting hundreds of data points into software to analyze small radii, angles, distances, or surface finish parameters.

Common electric vehicle applications

Right now, form equipment is used to measure a number of parts involved in EV. The most popular applications for contour and surface finish equipment, related to EV lies in internal mechanisms. First being battery-related applications—whether for the individual components of a battery cell, the seals, the battery housings, or the charging ports.

Each of these applications has critical features—with sizes ranging from a few millimeters to microns—to help confirm batteries are making contact, charging appropriately, not leaking, and are protected from debris. Battery production is one of the most common manufacturing outputs where form measurement is necessary.

Gears used in the transmission are another common part type with several important features which form equipment can measure with ease. A primary focus of these measurements is to identify how the gears will function, and perform over time.

An EV precision component is checked for surface smoothness to check for wear performance.

Overcoming electric vehicle measurement challenges

One of the biggest measurement challenges within the EV industry is the small size of the features.

That is why form measurement equipment is ideal for these applications, where a very small stylus is required to reach in, perform measurements and pick up the relevant point density.

Conversely, when it comes to measuring power control units (PCUs) or anything with a housing where form fit function is important, a CMM is typically used because of the 3D callouts and volume required to measure those parts. This includes electric motors in general.

A closer look at surface finish measurement

Surface finish measurements are typically taken in order to verify wear and performance of a surface. These measurements can be broken down into three profiles, roughness (R), waviness (W) and primary (P). The function of the part will determine the type of profile, as well as the type of surface finish gage needed.

There are specific requirements for measuring surface finish, including that the measurement should always be perpendicular to the lay of the material, and the surface parallel to the drive/datum.

This is where the importance of using the right equipment makes a difference. Whether it’s a hand gage, which can mount to a height gage or fixture to help keep the drive level to a surface, or more advanced CNC surface finish equipment, which can auto-level to surfaces and be programmed to automate all surface finish measurements.

For internal combustion engines you’ll see surface finish call outs such as Rmr, Rpk, and Rvk on locations where oil retention is required, to ensure that when oil is applied there is area to retain it. You will also see parameters such as Rz, Rt, and Rp dealing with volatility of a surface, to prevent wear issues. In the EV industry the surface finish callouts are more concerned with fluidity and how the parts interact with each other. The parameters used are similar to parameters seen in the IC industry—Ra, Rz, Rt, etc.—but with smaller tolerances.

Training and operating implications

The growth in EV has surged in the last few years. So, measurement and training on EV applications is also a relatively new endeavor. The main consideration is that EVs require significantly fewer parts than their gas-powered counterparts coupled with the fact that batteries are fairly standard across all vehicle types, vs. four-cylinder or six-cylinder engines. Because of this, CNC equipment is becoming more popular, providing manufacturers with automation and helping to see a much quicker return on investment.

Training on CNC equipment tends to be more involved. It requires an understanding of GD&T, coordinate systems, and for more advanced applications, the ability to use programming languages. Once these skills are learned and applied to CNC equipment, a significant improvement to accuracy and throughput will be seen.

A surface tester checks the smoothness and roundness of a tiny pin that requires exacting tolerances.

Existing electric vehicle measurement trends

Currently, there’s a trend toward noncontact measurement in most manufacturing, as well as the EV arena. Manufacturers want to make sure parts for battery applications remain smooth, scratch-free and untouched—that’s why the industry is moving toward noncontact measurement. However, when it comes to measuring with a light or laser, there are still many challenges such as reflective surfaces, achieving data density down to nanometers, and the fact that metrology equipment utilizing lights or lasers are typically more expensive.

The future of form measurement in electronic vehicles

Form measuring equipment certainly isn’t going anywhere. It will continue to be an integral part in measuring small features for electronic vehicles, as well as a great tool for R&D departments to identify quality issues and improve products. Looking ahead, the biggest changes to come will be in terms of technology around the accuracy and affordability of 3D, noncontact surface and contour measuring equipment.

And while, at this time, there aren’t different standards for form measurement in electric vehicles vs. standard automobiles, EV manufacturing is still in its infancy and new standards are likely to evolve as the market grows.

What to look for in a form measurement machine

For those looking for form measurement equipment, these are the top five things to consider:

- Repeatable true CNC positioning

- Capability to measure small features

- Product robustness & life expectancy

- Flexibility between contour and surface finish measurements

- Simple, easy-to-program equipment

In addition, when investing in CNC form equipment, it’s important to look for a system that meets these capabilities and criteria:

- Can create Work Coordinate systems

- Is a closed looped system

- Knows location of stylus tip at all times

- Is programmable on all axes

These functions will guarantee that the measurement routine will avoid crashes by moving to the correct location every time. This is especially crucial when measuring areas such as small IDs and bores, where non-CNC form gages have a tendency to crash due to not knowing their true location.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!