Case Study

MRB Guss Ensures the Quality of Its Cast Parts with X-ray

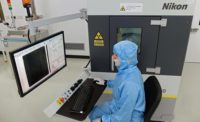

With an x-ray inspection machine, the company is able to guarantee the quality of the castings faster and more comprehensively.

All Images Source: Zeiss Manfred Stich

Since December 2020 MRB Guss GmbH Herzogenburg near Vienna has been assuring the quality of iron castings with the ZEISS BOSELLO MAX 450kV machine, an investment that is paying off. With this X-ray inspection machine, the company is able to guarantee the quality of the castings faster and more comprehensively. These benefits are helping the firm produce more efficiently and attract new customers.

It’s dark, dusty, loud and warm. And yet it’s a fascinating place: the composition hall of MRB Guss GmbH. This is where, each hour, 12 to 13 tons of metal are melted in two medium-frequency ovens in tandem processing. It’s a lot of material that must be handled quickly. Which is why the red-hot molten mass from the holding furnace is poured several times an hour into a huge temperature resistance treatment and transportation container (the so-called GF converter), which is then mounted onto a forklift. This happens so precisely that not a single drop of the approximately 1,530 °C hot mass falls to the ground. Before the operator drives the hot load to the casting plant, he inspects the temperature for quality purposes using an approximately 2-meter-long measuring probe. Afterwards, he adds pure magnesium or a master alloy to the reaction chamber. The ensuing exothermic reaction, whereby the magnesium evaporates and the melted mass desulferizes and amalgamates, creates a fireball that rises from the so-called converter. This lasts around a minute. Following this infernal noise, the forklift driver moves forward and dumps the mass for the cast iron together with ductile iron into the casting furnace at the molding plant.

This particular process is complex and “can only be mastered with a lots of foundry knowhow,” explains Michael Gundacker, director of quality management at MRB Casting. Casting iron parts is therefore a “true art.” And that applies just as much to Gundacker’s own job, which is extremely demanding given the many types of influences that can affect the quality of the cast parts. But, says Gundacker, who began his career in another industry, “that fascinates me here.” That attitude will certainly please the two managing directors of MRB Guss, Markus Rosenthal and Ralf Bachus, as they too have found their calling in iron casting. Or, as they describe themselves in the company’s image brochure: Once a foundryman, always a foundryman.

Quality Is Everyone’s Business

The art Gundacker refers to entails, among others, keeping the melting and casting process stable enough so the desired material and parts are produced in the required quality — and all that while keeping a tight eye on cost. Furthermore, there is the responsibility for the environment, which is a growing priority for MRB Guss. The company wants to “continuously increase the energy efficiency of the castings during their manufacture.”

This goal can only be achieved if the scrap rate is low. The reason is that remelting incorrect parts consumes a lot of energy. And if errors are discovered at a later stage of the processing, then the overall energy efficiency further worsens due to the need to process the parts again and re-transport them to the customer. By investing in the ZEISS BOSELLO Max 450kV X-ray machine, MRB Guss is well positioned to confront this problem. But we’ll get back to that later. As said, the quality of the castings is determined by various factors. These range from the temperature of the melting process and the speed of the casting process to the design of the casting mold. Therefore, ensuring that the high quality standards are met is not only the task of Gundacker and his 10-person team, but also of every one of the 240 employees. “They understand their craft and assume responsibility for their work.”

The fact that everyone is working towards the same goal can be traced mainly to the leadership style of the two managing directors, asserts 33-year-old Gundacker, who joined the firm in 2019. The managing directors value “everyone and every type of work they do.” In addition, everyone has “an open ear for personal problems and they help where possible.” This motivates the staff “to give their best.”

Short Distances, Fast Decisions

This attitude also helps the company remain flexible and respond quickly to the needs of its customers. Moreover, the hierarchies are flat so decisions can be made fast. That wasn’t always the case. Before the two CEOs established MRB Guss GmbH, they managed the iron foundry Georg Fischer Casting Solutions in Herzogenburg and were therefore part of a complex company structure. According to quality manager Gundacker, the management buyout in 2019 was a “strike of luck for the iron foundry.” Now, without endless rules and guidelines, “we can make decisions within a few hours.” And that, emphasizes Gundacker, has had a truly tangible impact. For example, if the management had not immediately decided to invest in a paint shop, “we wouldn’t have won a very important client.” And that was no exception. Within just two years of the management buyout, MRB Guss won 18 new customers and expanded its customer base to a total of 31 – including such well-known names as BMW, VW, MAN, LIEBHERR, GEA or CLAAS.

Flexible And Diverse

To survive in this industry, says Gundacker, “you have to fulfill the requirements of the clients.” That begins with the quantities. In Herzogenburg, MRB Guss produces not only large automotive series of 500,000 parts a year, but also small prototype series beginning at 50 pieces.

Furthermore, the company does its own in-house model-building and fixture design. They design and/or optimize the CAD designs of their customers, and thanks to its investment in smaller production machinery, the company can work just as efficiently on small and large lot sizes and paint them too, if desired by the customer. The combination of these conditions, the company’s comprehensive foundry knowledge and its ability to make all cast-iron materials means MRB Guss GmbH is not only able to attract more customers. A glance at their customer list reveals they are also serving the needs of companies from a wide range of different industries.

The exhaust manifolds, crankshafts or differential casings produced by the company are also needed by manufacturers of construction, commercial and agricultural vehicles. This development is preparing the Austrian company, whose roots in Herzogenburg go back to 1862, “to confront the upheaval caused by OEMs’ retreat from combustion engineering,” says Gundacker.

Quality That Stands Out

“But ultimately, all our flexibility is worth nothing if the quality is not right.” Gundacker, a trained mechatronics engineer, knows what he’s talking about: until 2019, he was on the other side and evaluated suppliers for his former employer.

The measurement devices and inspection methods that are currently used at MRB Guss GmbH are broad and diverse. The company is also certified for quality management system IATF 16949:2016 and ISO 9001:2015.

In addition to analyzing the sand (from which the castings are formed) and the molten mass, the cast parts are of course also inspected. It is common in this industry to cut open and analyze sample parts. Where exactly the cut happens is determined by a simulation program, which shows the probabilities for porosities, bubbles or inclusions. “However, this method can’t tell us for sure if there are defects in other areas of the part,” says the quality manager. In the worst case, the errors become apparent during the processing and occasionally after the part has already reached the customer. That is not only a cost and environmental problem. The company’s image suffers too.

To avoid this from happening, the MRB Guss has been using an X-ray device in Herzogenburg since December 2020. “It’s a big step forward for us – also for our customer acquisition,” explains Gundacker. Many foundries still do without this form of quality assurance; as a result, they lack a truly comprehensive inspection of their parts. But more and more customers require it and “are not satisfied anymore with just probabilities.” Which is why Gundacker always makes sure the X-ray device is shown to clients during every customer tour of the premises. It’s his ace, so to speak, which helps him win the game.

One Device, Many Benefits

The ZEISS BOSELLO MAX 450kV X-ray machine is used in particular to check the initial master sample and inspect random samples. Only one client, from the aviation sector, wants to X-ray all parts with it.

Although the machine is rather new, its benefits are already apparent. For example, the startup time for series production has been shortened. That’s good news not only for customers, since they receive their parts faster. It also makes the production more profitable. The in-depth and comprehensive X-ray results allow for a detailed target/actual comparison with the simulation. As a result, the quality of both will improve in the future. The X-ray data also immediately offer added value for the design and/or for optimization of the CAD models in order to fulfill the technical casting requirements. “The data can help us avoid errors before they even happen.”

However, the most noticeable benefit, says Gundacker, is that the company can now react faster thanks to the ability to do nondestructive and comprehensive inspection. In other words, if the operators of the X-ray machine detect defects at the relevant spots, parts that are affected can be sorted out immediately and taken out of production. This also increases profitability and therefore secures Herzogenburg as a place to do business.

A Tough Selection Process

Although MRB Guss already uses measurement devices from ZEISS and is extremely satisfied with the support it receives, selling an X-ray device that costs several hundred thousand euros didn’t come automatically for the ZEISS sales team.

Given the price of the machine, MRB Guss got offers from various companies. Each company received typical components and was asked to conduct a feasibility study with those parts. This approach already separated the wheat from the chaff. Not every manufacturer was able to demonstrate a high resolution for the castings, for example, for a 600 mm-long exhaust manifold.

In addition to the performance and support from ZEISS, something else worked in ZEISS’s favor: the size of its machine. Weighing in at 14-16 tons, the ZEISS machine weighs half as much as other X-ray machines that have the same performance. The design of the ZEISS device explains why it can be so compact while still providing the operator with the necessary radiation protection. Instead of having to move tubes and the detector together at the same time, these can be controlled separately. And because less mass has to be moved, the operator can move it into the right position faster, which in turn speeds up the entire process.

Although a device with lower performance would have sufficed for X-raying most of the castings in the existing product portfolio, the company’s management decided on the machine with 450 kV. As a result, it can X-ray metal measuring up to 50 mm. For Gundacker, purchasing the ZEISS device was a “future-oriented decision that is paying off for this location.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!