Home » lean manufacturing

Articles Tagged with ''lean manufacturing''

2021 Quality Plant of the Year: Electromed, Inc.

This medical device company and essential business faced extraordinary pressure to keep up with demand while managing its own safety in a pandemic.

March 5, 2021

Developing Skills while Giving Back

ASQ's core strength is its local presence.

June 30, 2020

Lean ISO Management Systems: How to Create Lean Procedures

The objective is to eliminate or minimize waste within the process without impacting the outcomes.

May 1, 2020

The Value of Membership

Maximize the value you receive for your membership dollars.

January 8, 2020

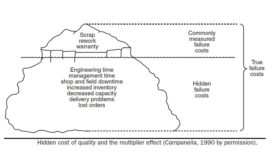

Prevention is the Key to Reduced Quality Costs

Customer-facing processes must be designed to prevent errors and minimize cost of failure.

November 8, 2019

Visual Management Helps Improve Quality

As we practice lean, we put things like 5S and visual management tools into place.

October 8, 2019

The State of Sensors in the Industrial IoT

Better quality is possible with IO-Link and machine learning.

August 8, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing