Home » data analysis

Articles Tagged with ''data analysis''

Sponsored Content

Preventing both warranty issues and field problems due to lack of product reliability.

Read More

Sponsored Content

Helping Tate & Lyle Ensure Sweeteners Feel More Like Plain Sugar

When they faced a challenge in the process of refining corn sugars, Tate & Lyle turned to Minitab software for assistance.

February 11, 2022

Sponsored Content

Hitachi's Industry Executive Greg Kinsey: Black Belts Can (and Should) Drive the Digital Transformation of Manufacturing

The digital transformation of manufacturing is broadening the toolkit and opportunities for Six Sigma’s DMAIC process.

February 10, 2022

Sponsored Content

Minitab Launches New Real-Time Statistical Process Control Solution for Manufacturers

Real-time monitoring and alerts allow for immediate action when quality varies, saving both time and money.

February 7, 2022

Ask the Expert | Dr. Sophronia Ward

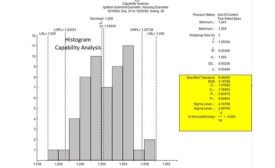

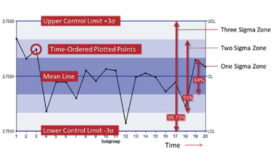

Capability Analysis Follow-Up

Here we'll cover the specifics of a capability analysis and several sticking points in interpreting and taking action on information from the analysis.

May 7, 2021

What Should Analytics Add to a QMS Solution?

The Third Wave is on its way.

January 6, 2021

What Is the Cost of Quality in Manufacturing?

Having a low-quality product can be more expensive.

October 8, 2019

Sponsored Content

4 Steps for Data Collection along the Industrial Internet of Things Path

July 15, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing