Home » phased array

Articles Tagged with ''phased array''

NDT | Trends

Corrosion is complex, and mitigating and managing it is not a linear process.

Read More

NDT

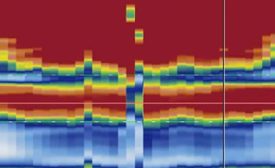

The Advantages of Phased Array Technology

When evaluating welded tubes.

February 15, 2021

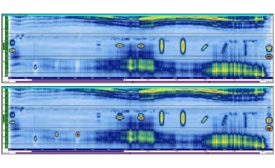

A New Angle on Aerospace FSW Inspections

The most effective inspection method for friction stir weld flaws is phased array ultrasound.

July 1, 2020

Easing the Inspection Task

Recent developments in various NDE modalities are making inspection more accurate and faster while providing data that is easier to interpret.

June 10, 2020

Using Full Matrix Capture to Maximize the Capabilities of Your Portable Phased Array UT Device

Simplify and improve the inspection of complex geometries and dissimilar materials.

October 8, 2018

NDT on the Flight Line

A midair engine failure in April puts nondestructive inspections to the test

July 8, 2018

Using Phased Array UT for Austenitic Weld Inspections

How the latest phased array ultrasonic testing tools and techniques allow more productive NDT.

June 1, 2018

Transformative Technologies and What They Mean for Inspection

These technological advances stand to impact all nondestructive testing methodologies.

February 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing