Home » phased array

Articles Tagged with ''phased array''

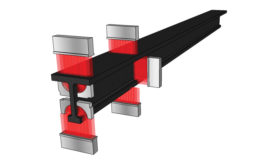

Short Range Guided Wave Ultrasonic Testing

Make inspections more accurate.

November 13, 2017

The Advantages of Adaptive Ultrasonic Phased Array for Inspecting Composite Aircraft Components with Complex Geometry

Ultrasonic phased array technology is widely used to inspect composite components in aircraft.

August 1, 2017

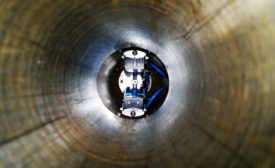

Ultrasonic Inspection Approaches for Measuring Corrosion Wall Loss in Process Piping

The direct and indirect cost of corrosion can be staggering.

November 1, 2016

Ultrasonic Testing of Metal Bars and Tubular Products

Whether manual, automated, or phased array, ultrasonic testing can help manufacturers of bars, tubing, and related metal products to ensure product quality and customer satisfaction.

October 12, 2015

NDT - Phased Array

Parallel Phased Arrays to Achieve High-Speed Inspection

Automation and parallel phased array systems are being used to meet challenging inspection and production requirements.

October 10, 2013

NDT - Ultrasonics

Market Analysis

Where is The Ultrasonic Nondestructive Test Equipment Market Headed?

June 12, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing