Home » machine vision

Articles Tagged with ''machine vision''

V&S HEADLINE

Adept Technology Opens Robotics Application, Demo Center in Ohio

September 12, 2014

V&S HEADLINE

North American Machine Vision Market Posts Record First Half in 2014

September 3, 2014

V&S HEADLINE

Vision Engineering Welcomes New North American Metrology Manager

August 19, 2014

V&S HEADLINE

The Association for Advancing Automation Sets Membership Record

August 13, 2014

Turnkey Systems

Set Your Limits

Fine tune machine vision limits for optimal product Quality and yield

July 2, 2014

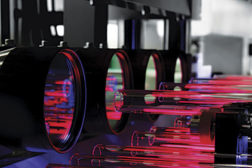

Machine Vision Systems

Machine Vision Components

Learn what to keep in mind when selecting machine vision components.

July 2, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing