Home » sensors

Articles Tagged with ''sensors''

VISION & SENSORS - SENSOR TRENDS

We can replicate the efficiency of how our eyes work with a new form of vision capture called event-based vision.

Read More

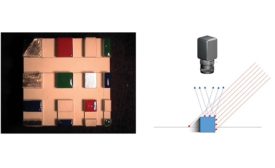

Three Cornerstones of Smart 3D Machine Vision

Modern UI design, web-enabled 3D smart sensors, and onboard inspection software.

November 28, 2020

Destroying Materials is Critical to Saving Lives

Recent developments and improvements in testing equipment, sensors, and knowledge have led to a significant increase in high speed and high rate material testing efforts.

August 3, 2020

Trends in Machine Vision Sensors

Predictive maintenance, OPC unified architecture, and quantum dot technology are just some of the new buzzwords in this space, according to industry experts.

December 2, 2019

Illumination: The Third Pillar of Imaging System Design

Illumination is an often-overlooked yet crucial aspect of vision.

September 1, 2019

Choosing Sensors for your CMM

The goal of part inspection is to get results you can trust.

July 1, 2019

Measurement

Sensors Unmasked: The Changing Face of CMMs

Evolution is afoot in traditional measurement systems.

May 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing