Home » sensors

Articles Tagged with ''sensors''

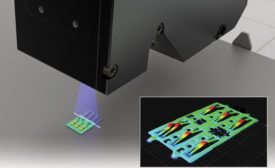

Designing a Better Sensor for Small Parts Inspection

Smart technology advancements are at the heart of today's movement toward better sensor design.

March 1, 2019

Q&A: 3D Smart Sensors, Deep Learning, and The Future of Automated Quality Control

The CEO of LMI Technologies describes how 3D sensors are integral to a new era of quality.

March 1, 2019

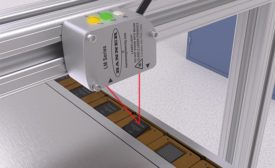

How to Choose a Precision Measurement Sensor: Key Considerations

In precise part inspections, a reliable solution is a must.

March 1, 2019

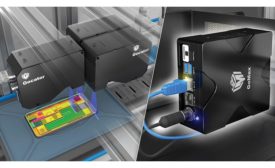

Smart Cameras vs. Profile Sensors

An application-based guide on which to use.

December 1, 2018

Sponsored Content

Trends in 3D Inspection: Edge Computing, Acceleration, and 3D Smart Sensors for IIoT

October 30, 2018

Sponsored Content

Easy and profitable measurement solutions using smart laser triangulation sensors

October 30, 2018

When to Use a Vision Sensor

Vision sensors are an especially great choice for users that are getting started with vision.

July 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing