Home » automation

Articles Tagged with ''automation''

Quality Web Exclusive

Automated Objectivity: Eliminating Quality Testing Subjectivity

April 18, 2019

XRF Analysis: What Labs and Lines Really Want—and New Features That Get Them There

Everyone’s ultimate goal: minimal variation, maximum speed.

April 8, 2019

As Automation Grows, Microscopes Evolve

Industry 4.0 advances a variety of microscopy solutions.

April 1, 2019

Robot, Robots, Everywhere!

Robots are the go-to tool for manufacturers wanting to increase throughput along with quality and efficiency.

April 1, 2019

Automation: The Union of Efficiency and Repeatability

A fully-automated system requires minimal training and provides reliable results.

February 1, 2019

QUALITY WEB EXCLUSIVE

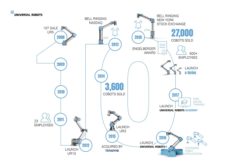

Universal Robots Celebrates 10 Year Anniversary of Selling the World’s First Commercially Viable Collaborative Robot

Universal Robots marks a decade of pioneering collaborative robots, now the fastest-growing segment of industrial automation.

January 3, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing