Home » automation

Articles Tagged with ''automation''

Automobiles and Automation

From the wheel and horse to the push of a button.

January 15, 2020

Improving Your Manufacturing Productivity and Quality with CMM Networking and Automation

Consider automating and moving your CMMs to the shop floor.

January 1, 2020

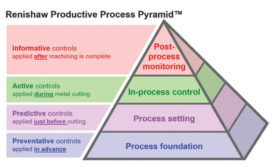

Post-Process Monitoring, Part 2

Robotic automation and post-process monitoring

December 6, 2019

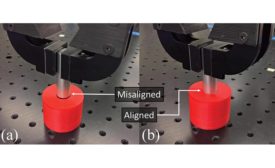

Helping Robots Stay on Target

Both accuracy and repeatability are key performance characteristics that influence the robot's ability to meet a manufacturing process's needs.

December 2, 2019

Post-Process Monitoring

Its relationship to additive manufacturing, automation, and more.

November 25, 2019

Leak Testing Complex Systems: Recommendations & Best Practices

The leak testing process is a crucial quality control method that helps manufacturers ensure that their final product will be safe and reliable for end users.

August 1, 2019

Increasing Productivity with CMM Automation

Discover how shop floor equipment can simplify your measurement process.

August 1, 2019

Vision Robotics Takes Off

Machine vision and robots continue to solve problems on the factory floor.

May 8, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing