Home » quality assurance

Articles Tagged with ''quality assurance''

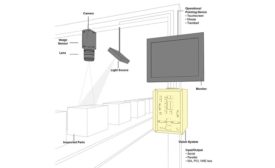

A competent vision designer can optimize image capture at extremely high speeds.

Read More

A Quality Assurance Toolset for Modern Manufacturers

Before you can fully utilize machine vision, you need to understand the basics.

January 8, 2020

Sponsored Content

What Can Go Wrong, Will Go Wrong: Learnings From Quality Case Studies

July 30, 2018

Achieving Consistency and Reliability in Additive Manufacturing

How to create and maintain a quality assurance process.

April 16, 2018

INDUSTRY HEADLINE

ECM Awarded Official Approved Supplier Certificate of Measurement and Programming Services from Rolls-Royce Corporation

February 13, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing