Home » quality assurance

Articles Tagged with ''quality assurance''

NDT | PMI Part 1

PMI is a vital nondestructive testing method for quality assurance and safety.

Read More

Software

Harnessing ChatGPT to Develop Calibration Procedures for Test and Measurement Equipment

While AI cannot entirely replace human expertise in developing calibration procedures, it can certainly enhance and streamline the process.

October 4, 2023

Quality in Automation | Industry 4.0

Connected Quality Is the Secret Sauce to the Fulfillment of Industry 4.0

Integrating QC and QA can mitigate product quality risk and empower smarter factories.

April 6, 2023

Measurement

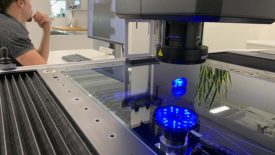

How to Measure the Intricate Components of Electrical Connectors

Quality assurance is critical for manufacturing electrical connectors.

March 30, 2023

Software & Analysis

Quality Software: Core Qualities to Build Specialist Software Tools in QC Metrology

Manual operations cannot fully meet the challenges of a competitive and increasingly digitized industry.

March 28, 2023

The Spending Forecast is Here

The 22nd Annual Quality Spending Survey Results

Concerns about Covid-19 are down, but inflation worries are up.

December 29, 2022

Spectroscopy Explained

Spectroscopy is the branch of science dedicated to the investigation of electromagnetic spectra produced from the interaction between a sample and an energy source.

October 29, 2020

The Unfolding Course of Events

Looking to the past provides some perspective.

June 30, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing