Home » quality control

Articles Tagged with ''quality control''

INDUSTRY HEADLINE

Metrology for Additive Manufacturing to Come of Age

Currently, there’s not enough data for designers and manufacturers to accurately predict the performance of some additive-manufactured parts.

April 10, 2018

Meet James Bossert from ASQ, our 2018 Quality Professional of the Year.

Continuous improvement has been a constant throughout a career that has spanned multiple industries around the country.

April 2, 2018

Trends in Sensor Technology for Quality Control

Advancements in laser measurement technology and the adoption of IO-Link communication are making complex inspections easier, more reliable, and more cost-effective.

March 8, 2018

Handheld XRF for Non-Standard Alloy QA/QC Applications

It can be used for new applications such as inspecting powder for sintered metal used in 3D printing.

November 13, 2017

Turnkey Machine Vision Integration Success

Let’s take a look at how you can succeed every time.

July 1, 2017

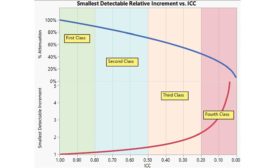

The Cost of a Poor Measurement System

Convince people of the value of measurement system analysis.

July 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing