Home » hardness testing

Articles Tagged with ''hardness testing''

Test & Inspection

The most important step is to familiarize yourself with the limitations of the test method to avoid inaccurate results.

Read More

Test & Inspection

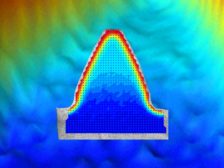

Advancements in Hardness Testing: Heatmapping and the Power of AI-Indentation Evaluation in the Metals Industry

An exciting addition to hardness testing is the integration of AI-based indentation evaluation, which enhances the precision and efficiency of hardness mapping.

February 15, 2025

Quality 101

Materials Testing: Getting It Right the First Time

Materials testing submits a material or product to a thorough, in-depth "check-up" to ensure overall quality.

January 31, 2024

Test & Inspection

The Right Hardness Testing Method for Your Metals Application

The right hardness test method depends on the material being tested and the specific requirements of the application. Understanding the differences among the available options helps determine which method will give you the best results.

January 1, 2024

Test & Inspection

An Introduction to Dynamic Micro-indentation Measurements

This article will highlight the broad applicability of the dynamic hardness technique.

December 21, 2023

Test & Inspection

Hardness Testing of Individual Battery Electrode Particulates

Recently, researchers have shown correlation between particle hardness and cycle performance.

April 4, 2023

Test & Inspection: Measuring Magnetic Properties

Measuring magnetic properties can determine the effect of heat treatment on a material

July 8, 2022

Test & Inspection: Hardness Testing of Coatings

There are a wide variety of testing techniques for hardness, using different principles and reporting different scales.

July 8, 2022

Test & Inspection

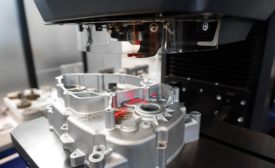

Digital Technologies in Hardness Testing

Modern computer control of hardness testers has advanced far beyond making a single line of indents.

October 1, 2021

Hardness Testing Changes with the Times

As 2020 marks the 100-year anniversary of the world’s first commercial hardness tester, the technology is as significant as ever.

February 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing