Home » ISO standards

Articles Tagged with ''ISO standards''

NDT | Standards

How Pulsed Eddy Current Technology Helps Uncover Corrosion

The main advantage of PEC is that it can inspect through insulation, weather jacket, and wire mesh.

April 12, 2023

Quality 101

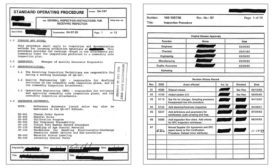

How to Lean Up Your Your ISO Documentation Structure

If you want to simplify your ISO documentation, look no further.

September 15, 2021

Additive Manufacturing Standards

Manufacturers should be aware of the many standards for this technology.

May 7, 2021

Remote Quality Management System Audits: An ISO 9001 Auditor’s Perspective and Lessons Learned

Planning in this remote audit environment is paramount.

December 5, 2020

Compliance and Convenience

If done well, a remote audit can be a useful tool.

October 1, 2020

Guest Editorial Comment

Quality in the Time of COVID-19

What a world we’re living in.

May 1, 2020

Lean ISO Management Systems: How to Create Lean Procedures

The objective is to eliminate or minimize waste within the process without impacting the outcomes.

May 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing