Home » 3D measurement

Articles Tagged with ''3D measurement''

Measurement

Closing the digital loop on arms, laser trackers, and scanners.

Read More

Measurement

Soaring to Success: How Laser Tracker Tech Enhances Maintenance, Repair and Overhaul Operations in the Aerospace Industry

3D laser scanning tools, like laser trackers in general, are helping radically improve the safety of an assortment of vehicles that take to the sky or space.

August 18, 2024

NDT | Automation

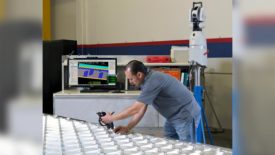

Enhancing Metrology through Automation: Elevating Quality and Cycle Time in Precision Manufacturing

The aerospace industry is one example of where the marrying of automation and metrology is being adopted to elevate product quality and operational excellence.

June 14, 2024

Measurement

Measuring Thickness Using Model-Based Metrology Software

Measuring and verifying the thickness of features is more critical than ever before.

January 26, 2024

Measurement

The Crucial Role of Support and Service while Investing in Multi-Sensor Metrology Equipment

In today’s fast-paced industrial environment, the right support and service can make all the difference between a successful investment and a costly disappointment.

December 29, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing