Home » tooling

Articles Tagged with ''tooling''

Let's look at how air tooling and its accessories are moving into today's modern manufacturing processes.

Read More

NDT News

NAM Survey: Manufacturers Continue Operating in Support of COVID-19 Response

August 5, 2020

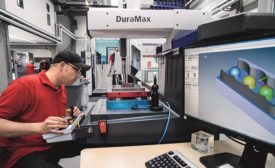

Fully Leveraging Machine Uptime

Offset measurements away from the machine tool boost manufacturing efficiency.

November 5, 2019

How to Create an AS9102 First Article Inspection Report

Despite the name, the inspected article may not necessarily be the “first” produced, but a sample from the first production run provided to the customer.

Read More

Boost Productivity, Profits with Active Controls

Increasing machine uptime has never been easier.

April 10, 2018

Modular Fixturing: How It Works

Many have found that modular tooling is a key decision making process for working with all types of measuring systems.

January 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing