Home » standards

Articles Tagged with ''standards''

Test & Inspection

The Journey to Creating an Inspection Standard

The scope of inspection is so vast that no one wanted to exclude a topic, but we also did not want a standard so detailed that it was not user friendly.

May 1, 2022

NDT | Liquid Penetrant Testing

ASTM E1417: Key Changes and Updates

In October 2021 ASTM E1417 was published, replacing the 2016 revision. This revision was completed as part of a standard review cycle, and to address changes in the industry.

April 1, 2022

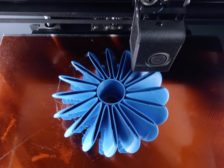

NDT | Additive Standards

Additive Manufacturing & Standards

When new industries, technologies, or processes emerge and grow, so does the need for standardization.

November 8, 2021

NDT | Certification

Nondestructive Testing Certification Programs Today

The need to formalize the qualification of NDT practitioners gradually became apparent.

October 15, 2021

Quality 101

Lean 101: An Introduction to Lean Manufacturing

Lean is about learning to see opportunities and continually improving them.

September 15, 2021

Quality 101

How to Lean Up Your Your ISO Documentation Structure

If you want to simplify your ISO documentation, look no further.

September 15, 2021

Quality 101

Quality Certification 101: Background, Process and Benefits

Quality certification is for professionals who know the chosen specialty so well that they can apply the knowledge with known results.

August 1, 2021

Aerospace | NDT AS9102

How to Simplify Your AS9102 First Article Inspection Process

What is First Article Inspection?

July 8, 2021

Additive Manufacturing Standards

Manufacturers should be aware of the many standards for this technology.

May 7, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing