Home » CT scanning

Articles Tagged with ''CT scanning''

NDT | Computed Tomography

Industrial CT-scanning systems and analysis software are providing faster insights into manufactured components.

Read More

Test & Inspection

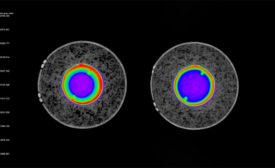

How CT Quality Analysis of EV Batteries Can Help Address Demand and Performance

Higher volumes of new batteries and faster turnaround of recycled materials from those batteries—along with testing of used and repurposed ones—demand the most efficient quality-inspection approaches possible.

September 27, 2024

NDT | X-ray CT

High Speed X-ray Computed Tomography for Quality Control

Advances in X-ray computed tomography enable rapid nondestructive, 3-dimensional inspection of die casted and molded parts.

May 20, 2024

NDT | Computed Tomography

Revolutionizing Manufacturing: The Growing Trends of Industrial CT Scanning

The adoption of industrial CT scanning has transformed product development, manufacturing, and delivery cycles across various industries.

May 15, 2024

NDT | Computed Tomography

Creating the Future of Mobility with CT Inspection of Batteries

Industrial x-ray and CT inspection supports quality control and failure analysis at all stages of a battery's lifecycle.

September 21, 2023

NDT | Computed Tomography

Industrial CT: 3D Inspection and Metrology for 3D Printing

CT inspection of the final part can check that the manufactured part exactly matches the initial 3D design, providing dimensional analysis and metrology of all critical internal dimensions.

October 15, 2021

Computed Tomography: Back to Basics

Computed tomography is a powerful nondestructive evaluation (NDE) technique for both 2D and 3D cross-sectional images of an object from X-ray images.

July 1, 2020

Nondestructive Inspection of Automotive Computers

As with the testing and evaluation of raw materials, controlling the quality of electronic devices is essential

April 8, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing