Home » 3D imaging

Articles Tagged with ''3D imaging''

A look at the most talked-about machine vision technologies, their practical uses and limitations, and which will have a long-lasting impact on your current and fixture applications.

Read More

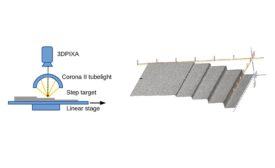

3D Stereo Camera Repeatability Measurement

Understand the process to determine measurement repeatability of a stereo 3D camera.

September 1, 2019

Sponsored Content

Time of Flight Gets Precise: Enhanced 3D Measurement With Sony® DepthSense® Technology

July 1, 2019

Q&A: 3D Smart Sensors, Deep Learning, and The Future of Automated Quality Control

The CEO of LMI Technologies describes how 3D sensors are integral to a new era of quality.

March 1, 2019

Computed Tomography Scans: The Latest Tool for Industrial Quality Evaluation

There is virtually no limit to the quality evaluation applications of CT scanning.

February 1, 2019

The New Science of Laser Trackers

Today’s enabling technology for “precision anything.”

September 15, 2018

Machine Vision Systems Integration

Techniques for putting the latest technologies and components to work in your applications.

September 4, 2018

CT Inspection: An Inside Look at CT-Based Nondestructive Testing

CT scanning has become an important tool for many research, industrial, and safety critical applications.

August 7, 2018

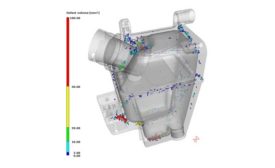

Radiography Trends Lead to High Speed CT

Today’s digital radiography is far beyond what early radiographers could have imagined.

April 2, 2018

3D Sensors in Machine Vision

As most players in the image processing industry know, there are several different ways to get a 3D image.

January 8, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing