Joel Martin

Joel

Martin is a product manager for Leica Geosystems Metrology Division

(Unterentfelden, Switzerland). For more information, e-mail

Joel.Martin@leica-geosystems.com, call +41 62 737 67 88 or visit

www.leica-geosystems.com.

ARTICLES

Large scale metrology grade scanning debuts this year.

Read More

The New Science of Laser Trackers

Today’s enabling technology for “precision anything.”

September 15, 2018

The Real-Time Promise of 7DoF Laser Tracking

A gateway to a new era of automation and factory of the future.

March 1, 2017

Tracking Progress: Re-evaluating Laser Tracker Technology

Handheld probes and scanners drastically expand possible applications

January 1, 2015

Test & Inspection

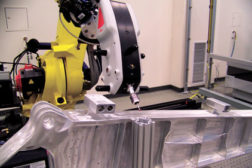

Metrology Automation is Here and Now

Robots and laser trackers are changing the landscape in manufacturing.

April 1, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing