Home » measurement systems

Articles Tagged with ''measurement systems''

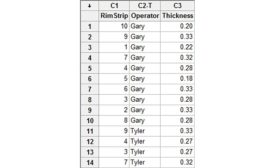

Missing the Point: Gage Variability and Operational Definitions

Clear operational definitions can prevent chaos.

April 16, 2018

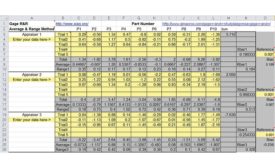

Gage R&R (Repeatability and Reproducibility)

Measurement system analysis can help you improve the quality of your products.

December 1, 2017

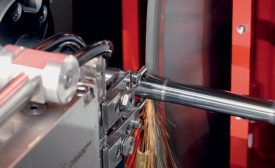

Gaging Quality As It Happens

The economies of in-process gaging are realized when high precision is required over large production runs.

November 13, 2017

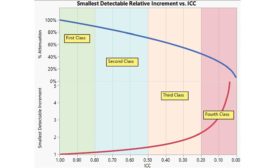

Is Your Measurement System Adequate?

If you can’t trust your measurement system, then you can’t trust the data it produces.

August 1, 2017

The Cost of a Poor Measurement System

Convince people of the value of measurement system analysis.

July 1, 2017

Calibration and Measurement Systems: The Unsung Hero in Quality Efforts

Timely calibration of all measurement devices is critical to manufacturing efforts.

July 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing