Measurement

The Importance of Grip Selection in Force Measurement

Putting these rules to work will dramatically improve sample alignment and measurement reliability.

February 1, 2017

INDUSTRY HEADLINE

Team Penske and Nikon Metrology Announce Technical Alliance

January 10, 2017

Proficiency Testing

Accrediting agencies require their labs to participate each year.

January 3, 2017

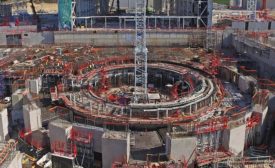

Controlling the Dimensional Quality of the World’s Largest Tokamak

Meet the prototype for future energy production across the globe.

January 3, 2017

Putting Surface Inspection in the Hands of the Machine Tool Operator

Manufacturers need tools for operators that meet test requirements and are simple to use.

January 3, 2017

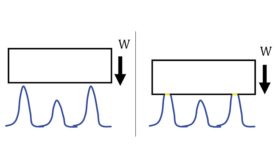

If you need less sliding friction, should you make the surface rougher or smoother?

Think quick!

January 3, 2017

INDUSTRY HEADLINE

Zeiss Opens Car Body and Automated Inspection Center in Michigan

December 2, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing