Measurement

Engineering Classic Design

Morgan Cars builds on its heritage of classic design with technology and innovation.

June 1, 2017

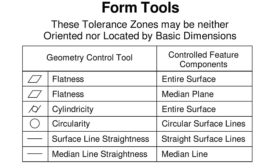

Empowering GD&T

Based on the ASME Y14.5 2009 Standard. Without GD&T, manufacturing is a guessing game.

June 1, 2017

Get to Know the Height Gage

The accuracy gets a boost when height gages with repeatable measuring force are introduced.

June 1, 2017

The Latest Trend in 3D Measurement: Line Confocal Sensors

FocalSpec is one of a few companies now offering these smaller, faster and more versatile sensors.

May 1, 2017

Making vs. Measuring

This was a judgment call based on experience and studies.

May 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing