Measurement

Gage management software not only helps manufacturers to manage gage accuracy, it also helps non-specialists to complete intricate analysis.

Read More

Measurement

Turning GD&T From Grim, Depressing & Troublesome Into Something Grand, Delightful & Tantalizing

For the sake of industries around the world, it is time to make GD&T much easier to use, and much easier to use correctly.

February 1, 2022

Column | Jim L. Smith

Face of Quality: KPI Fundamentals

Focusing on the right things is the key to success.

January 15, 2022

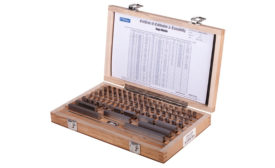

Calibration Matters More Than Ever

A manufacturer’s equipment is only as reliable as its calibration levels.

January 7, 2022

Quality Control With 3D Scanning

3D scanners are quick, accurate and record mass amounts of geometry, making them less laborious and more flexible than basic metrology tools.

January 3, 2022

Measurement

CMMs: The New Quality Makers

Geared up and ready to go for digital transformation

January 1, 2022

Column | Darryl Seland

Oh, Behave! Navigating Behavioural and Organizational Change

December 20, 2021

How Digital Gages Help to Advance Quality

As the industry embraces smart factories and automation, gaging software must seamlessly exchange information across all components in a production process.

December 10, 2021

Software & Analysis

Practical Reverse Engineering

Choosing the right tools for the job.

December 6, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing