Measurement

Measurement

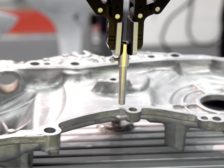

Although the CMM has been around for more than half a century, advancements have allowed it to maintain its position as the go-to technology for quality inspection.

Read More

Making A Case for In-Process Inspection

Implementing these in process inspections in real time helps manufacturers to avoid last-minute delays and averts wasting material.

October 11, 2021

Why In-line and At-Line Metrology Solutions Are the Next Step in Automated Quality

Manufacturers who want to completely automate quality control must rethink how to conduct quality in the manufacturing environment.

October 11, 2021

Column | Hill Cox

Other Dimensions: Settling Measurement Disputes

Not all parties to a dispute understand the importance of uncertainty budgets.

October 8, 2021

Column | Jim L. Smith

Face of Quality: Productive Failures

Failure can provide the seeds for success.

October 8, 2021

Measurement

Simplifying Metrology System Selection for Medical Applications

Tips for choosing the right vision system.

October 1, 2021

Column | Hill Cox

Other Dimensions: No Quote!

When you're fooling around with millionths of an inch, it doesn't take much to miss the target.

September 8, 2021

Column | Jim L. Smith

Face of Quality: Leadership

Effective leaders mentor the next generation.

September 8, 2021

Measurement

Modern Gaging Trends: Technology Evolves to Meet the Needs of Today’s User

Implementing these new technologies will make today's gages easier to use, offer more capabilities in an easier-to-read fashion and survive point of manufacture gaging.

September 1, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing