Test & Inspection

Part 2 of 2 - Practical Acceptance 'Limits' are a judgement call.

Read More

How Leak Testing Works

A leak test is a procedure used to determine if an object, product, or system functions within a specified leak limit.

February 8, 2020

Hardness Testing Changes with the Times

As 2020 marks the 100-year anniversary of the world’s first commercial hardness tester, the technology is as significant as ever.

February 1, 2020

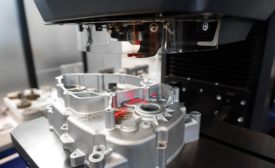

Trends in Automotive Inspection

Intelligent factories, electric vehicles and traceability are just some of the factors that are influencing change in automotive part inspection, say experts in the field.

January 15, 2020

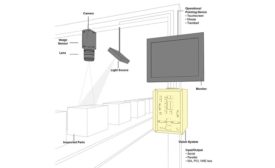

A Quality Assurance Toolset for Modern Manufacturers

Before you can fully utilize machine vision, you need to understand the basics.

January 8, 2020

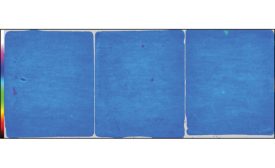

Analyzing Unexpected Structural Defects in Electronic Components

Anomalies may lie outside the scope of the established imaging parameters.

January 8, 2020

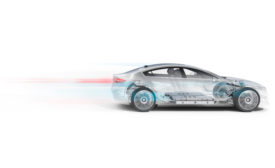

Introducing E-Mobility Inspection

Meet the quality inspection solutions for all components of E-Mobility: Battery, Power Electronics, E-Motor and Transmission.

January 2, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing