Test & Inspection

Multiple camera systems have been a fixture in machine vision for decades. What is new is the use of CXP.

Read More

Whose Acceptance Limits?

Part 1 of 2: Learn more about these boundaries of precision.

January 1, 2020

The Devil is in the Details: Choosing a Proper Grip for Tensile Testing

Tensile strength is an important parameter of engineering materials that are used in structures and mechanical devices.

January 1, 2020

Quality Headline

Nyman, Strategic Growth Exec for Fortune-Level Companies, Joins NDC Technologies as Prez

December 17, 2019

ECA Probes Improve Inspection Flexibility—in More Ways than One

Eddy current array results can be saved, shared, stored, processed, and compared at any time.

December 10, 2019

The Mechanical Properties of Plastics

Mechanical properties describe the material’s reaction to an applied force, such as tension, compression, and impact.

December 9, 2019

Manufacturers Show Their ‘Metal’ Using the Imaging Power of Digital Microscopes

Improving the quality of metal-based products.

December 6, 2019

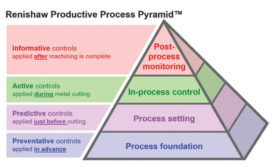

Post-Process Monitoring

Its relationship to additive manufacturing, automation, and more.

November 25, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing