Test & Inspection

Hardness Testers: Know Your Options for Best Results

Hardness testing functionality has evolved.

November 15, 2019

Quality Headline

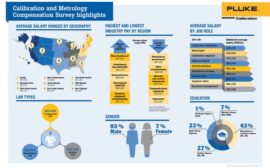

Fluke Calibration Publishes Third Annual Calibration & Metrology Salary Survey Results

November 11, 2019

Knapheide Saves Costs and Time in Nondestructive Vehicle Testing

The money saved would otherwise have been spent contracting outside test labs.

November 8, 2019

Automate and Robotize Your 100% Alloy Verification QC Procedure with Handheld XRF

Current advances in handheld XRF technology provide users with analytical results in real time.

November 8, 2019

Elemental Technology Comparison for Metal Fabricators and Manufacturers

Often the biggest challenge is choosing the right technology for your application.

November 8, 2019

Choosing and Applying NDT Methods for Round Stock during Production

There are many approaches to NDT inspection, ranging from full system tests to in-process inspection of partially finished products.

November 8, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing