Test & Inspection

Help us clear up the confusion of NDT terminology.

Read More

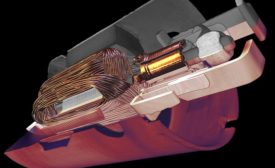

Computed Tomography’s Role

Accelerating time to market and improving profitability

March 3, 2021

Peel Applications

Lengthwise force testing for adhesives and interlocking materials.

February 8, 2021

Sponsored Content

White Paper: An Alternative to LVDTs = Lab Quality Linear Measurement Capabilities + Superior Industrial Gauging Performance

January 28, 2021

Sponsored Content

White Paper: Improve Your Stainless-Steel Testing with the Niton Apollo Handheld LIBS Analyzer

January 26, 2021

Standardized Leak Testing for Lithium-Ion Battery Cells

It is Essential for Automakers.

January 6, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing